AT6350U

Specification:

Max PCB size 400X500mm

Workable area :400X500mm

PCB thickness :0.5-5mm

Max thickness :8mm with custom-made jig

Max size :70mm x 70mm

Min size :1mm x 1mm

Max weight :80g

Accuracy :20um

Temperature control

Upper heater :350℃

Lower heater :350℃

Bottom heater :300℃

Control model 16 zones of programmable temperature setting for profile

Power consumption System total power 8000W

Upper heater :1000W

Lower heater :1000W

Bottom heater :6000W

Dimension:870*920*1580mm

Weight Appox :300KG

Input voltage :Single phase AC 220V 50/60Hz 8.0KW

Features:

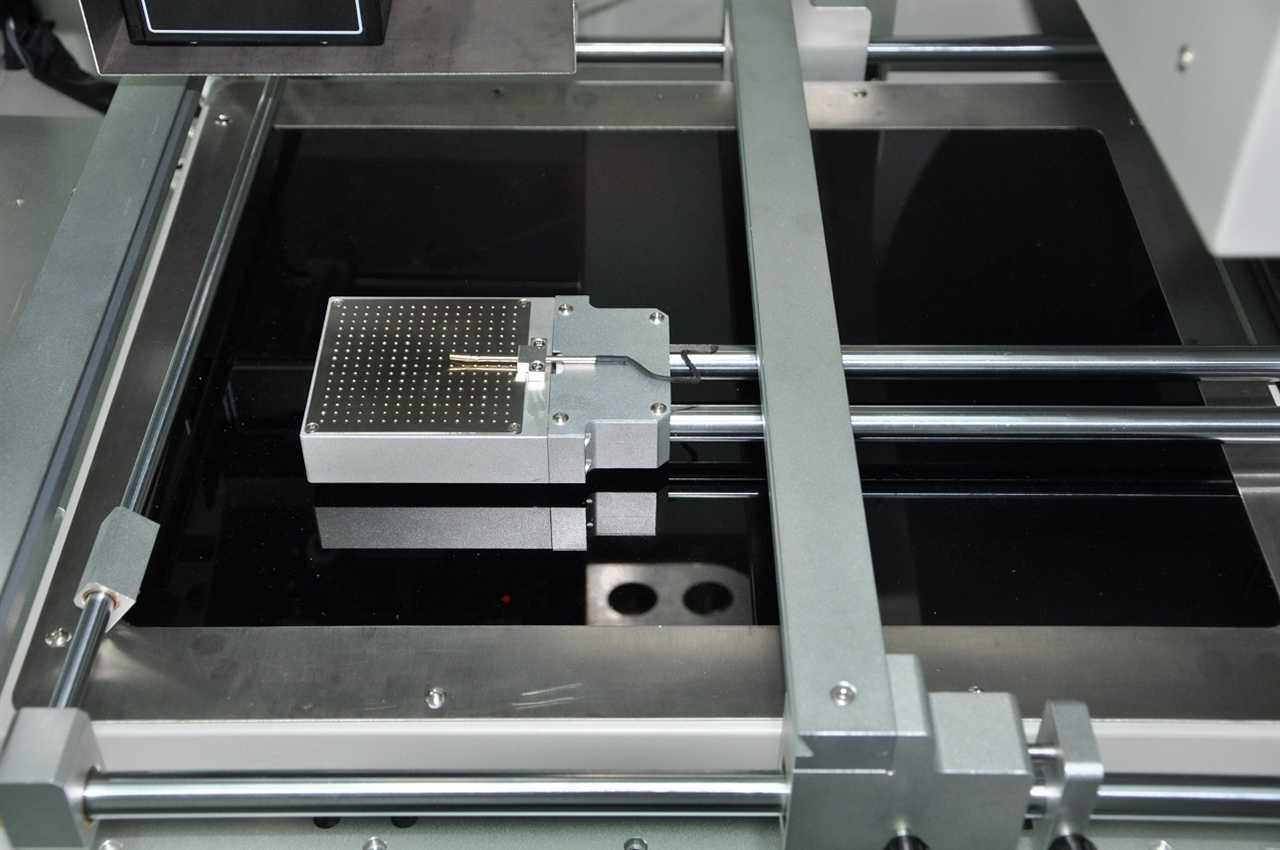

● Heater head and suction nozzle designed 2 in 1; functioned with auto-rotate, auto-align, auto-solder and auto-desolder;

● Suction nozzle move up individually, able to rework chipset 0101

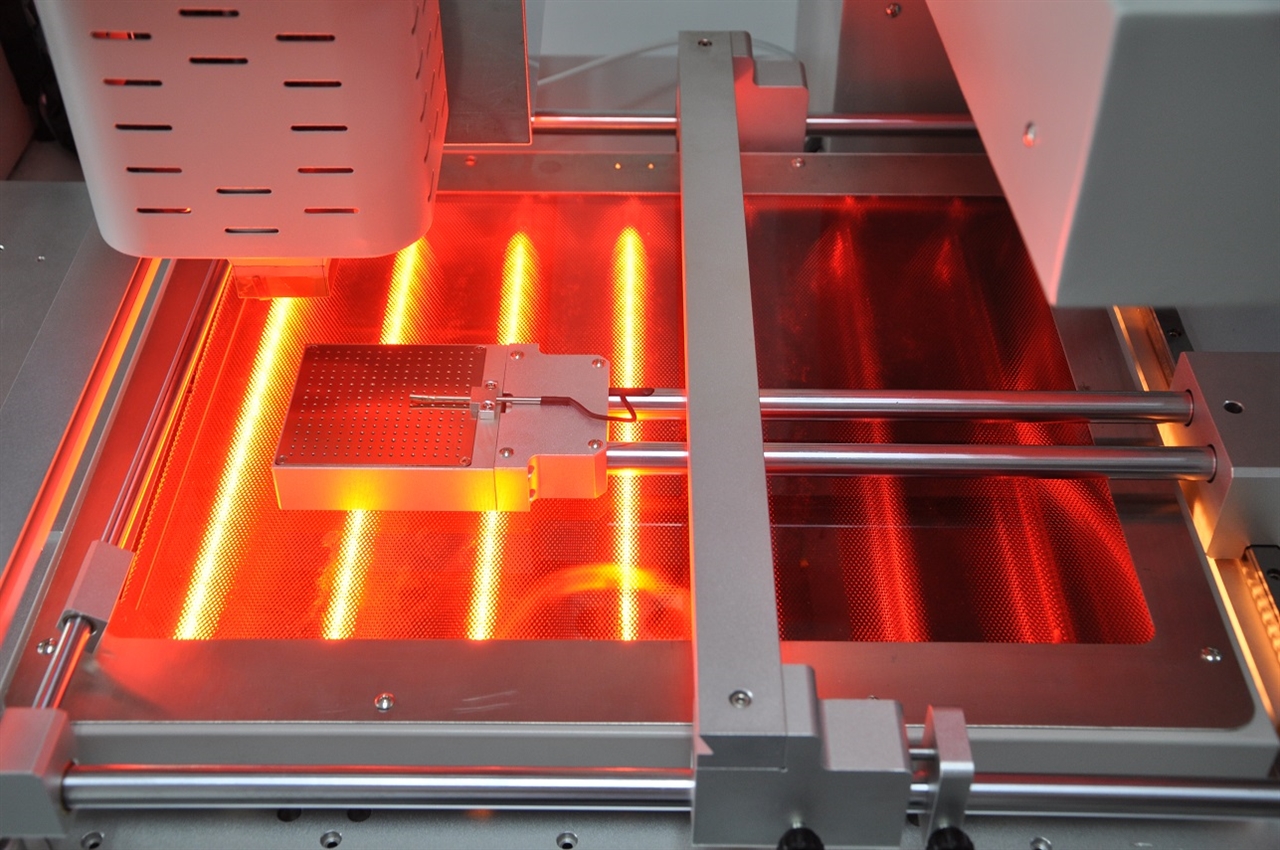

● While moving the lower heater, we can adjust its height, which can avoid the problem that the components on PCB are damaged during the lower heater is moving.

● 7 electric motors controls all actions; vision system, top heating system and under heating system are all controlled by joystick; makes alignment fast;

● The traditional temperature control mode of on-off control is replaced by analog quantity control, which makes temperature more accurate;

● Three independent heating systems, temperature and time can be displayed digitally on the touch screen, able to repair difficultly-reworked BGA; with alarm function in abnormal heating;

● The top heater adopts independent patent design, cooling and heating designed 2 in 1, which makes temperature control more accurate;

● The bottom heater is consist of 6 pieces of imported light-wave heating tube. With high-temperature glass plate, heating can be controlled individually.

● Bottom preheat area can be adjusted according to PCB size to heat the PCB evenly to avoid deformation and keep soldering effect; With function of over-heating protection and environment-friendly.

● Top heater driven by servo motor; suction nozzle can identify material and mounting height automatically, and can control the air pressure within a small range;

● Both upper and lower hot-air heating head are movable on the IR preheating area to fit for reworking BGA in different positions on PCB.

● PCB support holder can be pulled out and set length, which is easy for clamping PCB

● Laser pointer for alignment, easy for fixing PCB

● With function of Bar code scanner reading program;

● Color optical system with functions of split vision, zoom - in and micro-adjustment, equipped with aberration detection device; with auto focus and software operation function,27X optical focus; able to rework BGA sized up to 70mm*70mm;

● Touch screen interface, PLC control; able to display set temperature curves and five detecting temperature curves at the same time; 8 segments of temperature up (down) and 8 segments constant temperature control, more than 50000 groups of profile can be stored.; Profile analysis can be carried out on the touch screen;

● Built in vacuum pump; max. vacuum suction up to 80g,which can be micro-adjusted. Suction nozzle can be rotated in 360°;

● The supports rack can be adjusted to restrain the local sinkage of the BGA soldering area;

● Finished the BGA rework process under the nitrogen save through remain the nitrogen joggle in advance, have special function for saving nitrogen to save cost.

● Heater head and mounting head are designed 2 in 1 ,auto memorize different BGA heating positions and alignment positions;

● Alloy nozzle can be located in 360°;

● Adjustable universal BGA Reballing Kit, fixed BGA Reballing Kit (can be custom-made)

● Common stencils for laptop BGA 33pcs/set

● Universal stencils or particular stencils (can be custom-made)

● Equipped with different suction nozzles in various specification;

● Equipped with different alloy hot air nozzles (can be custom-made)