SP360C

Specification

Applicable PCB:

Max PCB size:430mmX350mm

Applicable BGA:

Max size:55mmX55mm

Min size:7mmX7mm

Max BGA weight:80g

Power for operation:4000W

Upper heater(hot air):800W

Lower heater(hot air):800W

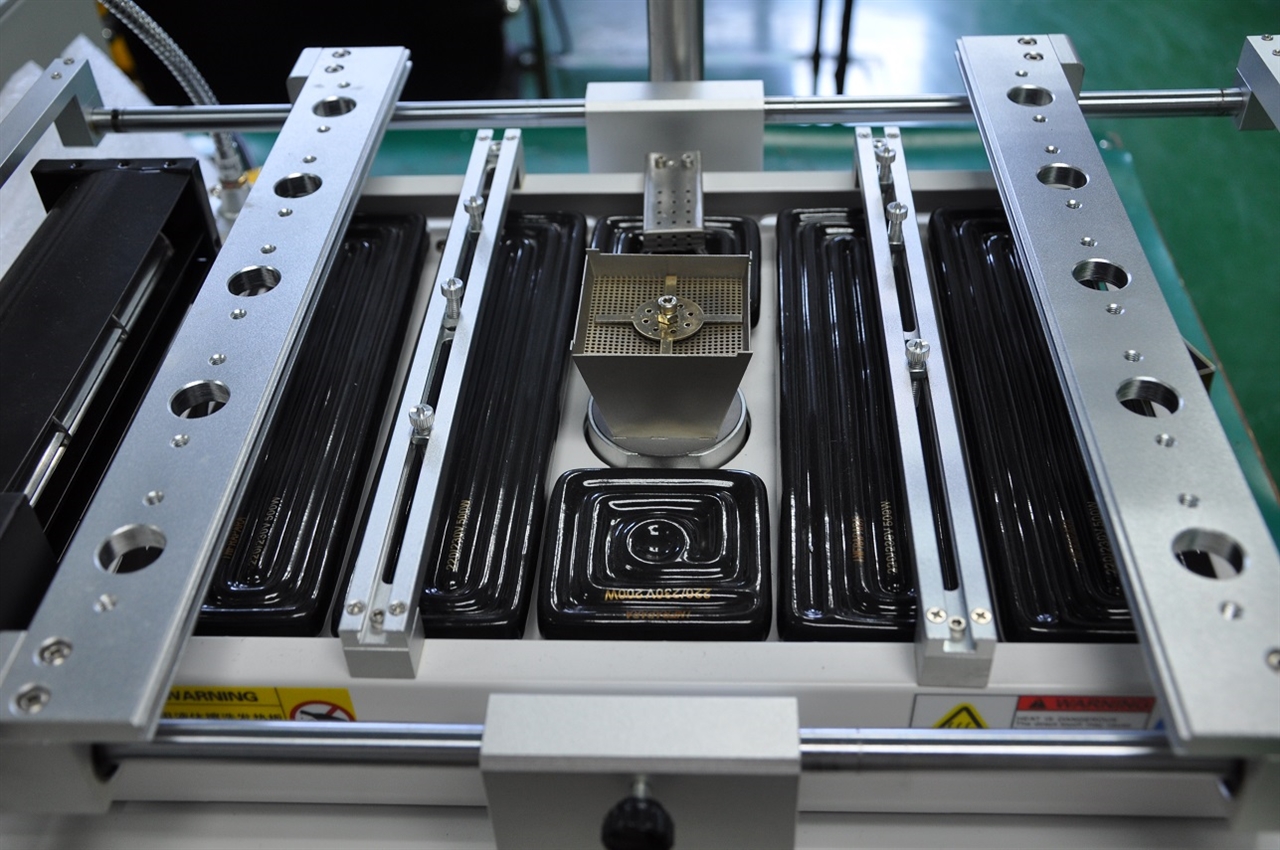

Bottom IR heater:2400W

Machine Dimension:650*500*600mm

Machine Weight:36KG

Power supply: AC 220V 4KW

Features:

●Made of high quality heating material; desoldering and soldering procedures

BGA are precisely controlled;

●Movable heating head, which is able to move freely horizontally, easy to operated;

●Embedded industrial computer, PLC control, real-time profile display, able

display set profile and practically-tested profile; big size screen, easy to operate;

●Profile saving no limit in this industrial computer, can analyze the two

practically-tested profiles, can input both English and Chinese;

●The temperatures of the upper and lower hot air heaters can be precisely controlled

according to their specific temperatures. The infrared constant temperature heating

zone at the bottom area and the appropriate temperature-control settings make

rework safer and more reliable.

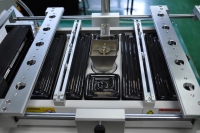

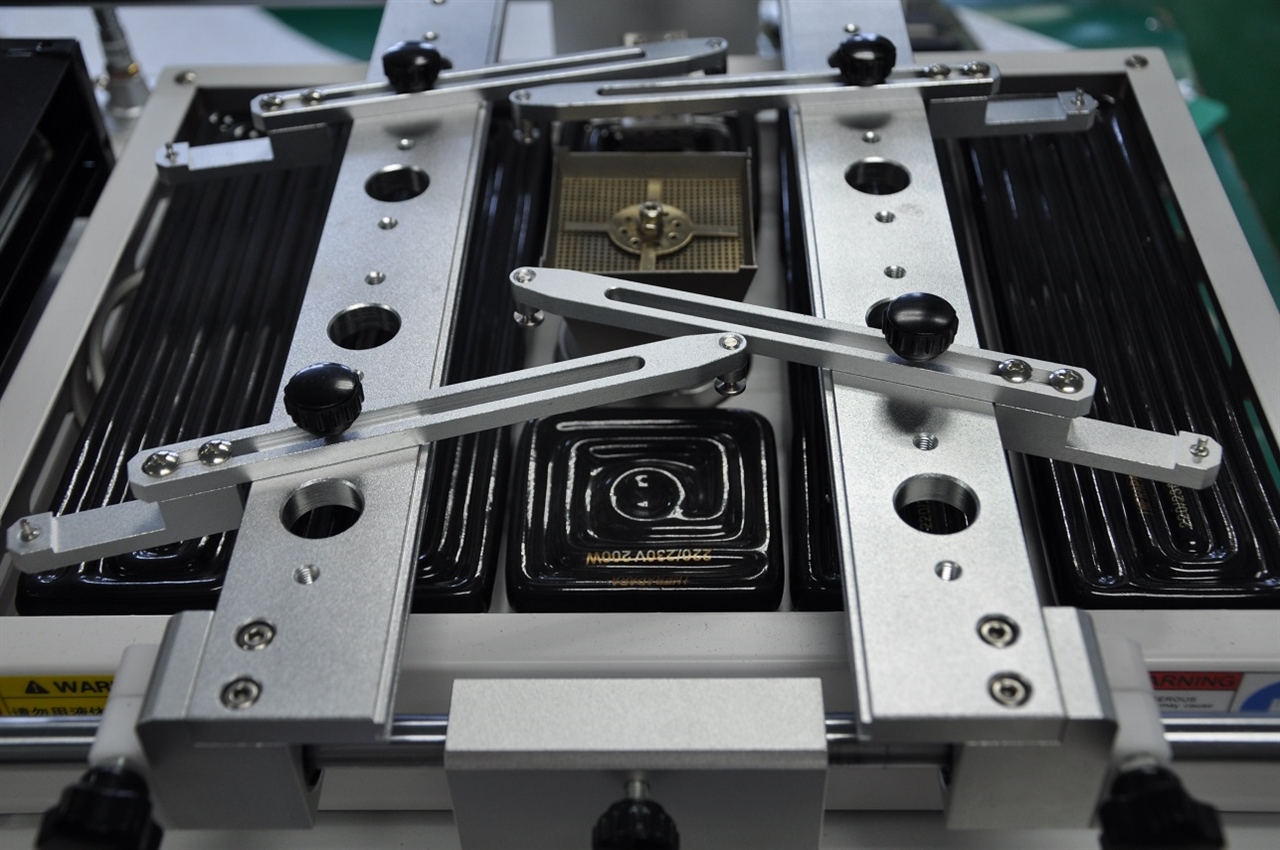

●The supports for the BGA soldering supporting frame are micro-adjustable

restrain local sinkage.

●Powerful cross flow fans cool the lower heating area rapidly;

●The adjustable PCB positioning support, onto which the special fixtures for alloyed

board could be installed, enables easy and fast positioning of the PCB board;

●Buzz after soldering is finished or desoldering; Hand vacuum pen is adjustable

removing BGA;

●Both the upper and lower parts are equipped with over-temperature alarming and

protection apparatus.

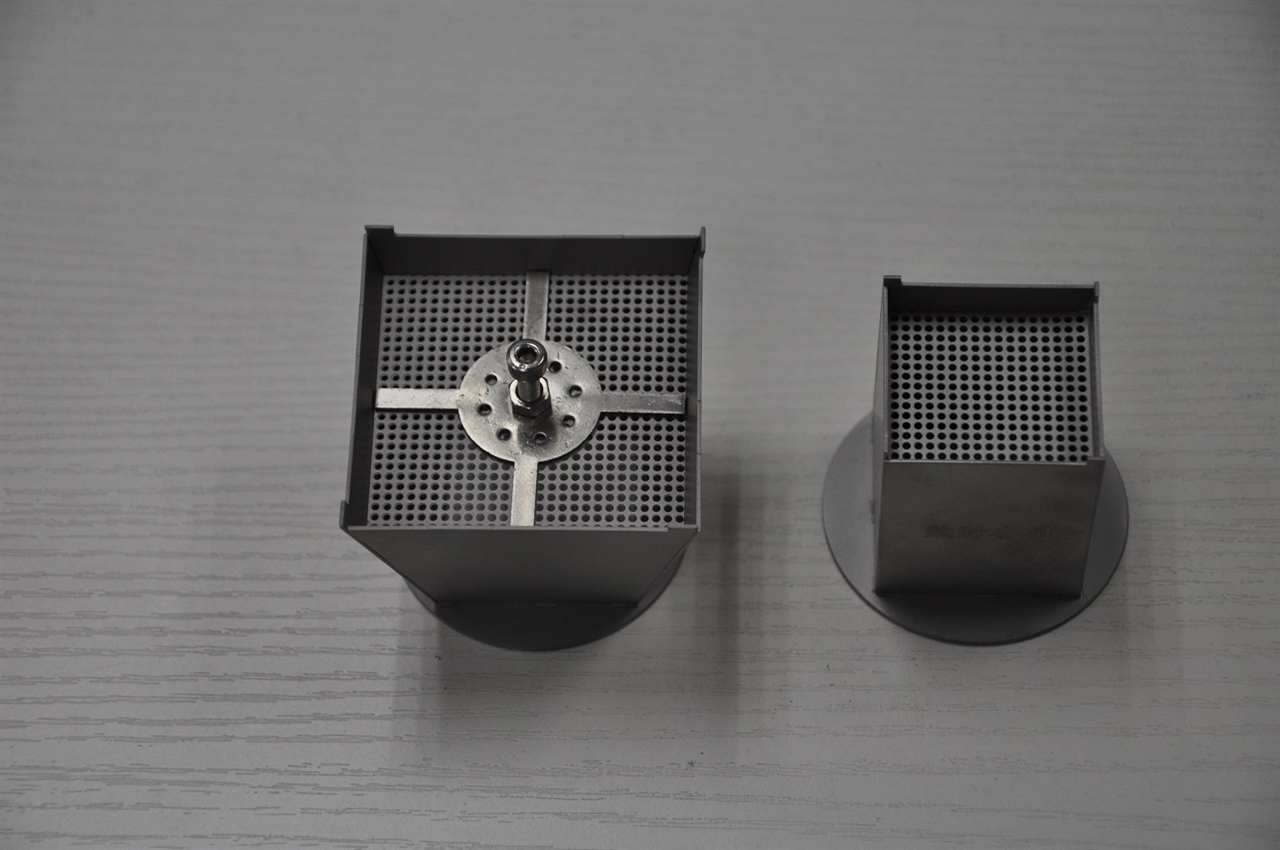

●With different alloy hot gas nozzles, easy to replace. It could be tailored as per

specific requirements.

●The integrated design of machine and chassis is room-saving. could be altered

instrument-control.

●The software can be updated to auto-profile in future by USB, no need to set profiles.

Video